Monitait vs. Excel: Why Smart Manufacturers Choose Monitait

Introduction: Excel has long been the go-to tool for data management and analysis in various industries. However, when it comes to smart manufacturing and production monitoring, Monitait stands out as the superior choice. In this blog post, we'll explore how Monitait surpasses Excel sheets in meeting the specific needs of modern manufacturing.

Specialization for Smart Manufacturing:

- Monitait is purpose-built for smart manufacturing, offering specialized features for production monitoring, quality control, and operator interactions.

- Excel, while versatile, lacks the tailored functionality required for manufacturing processes.

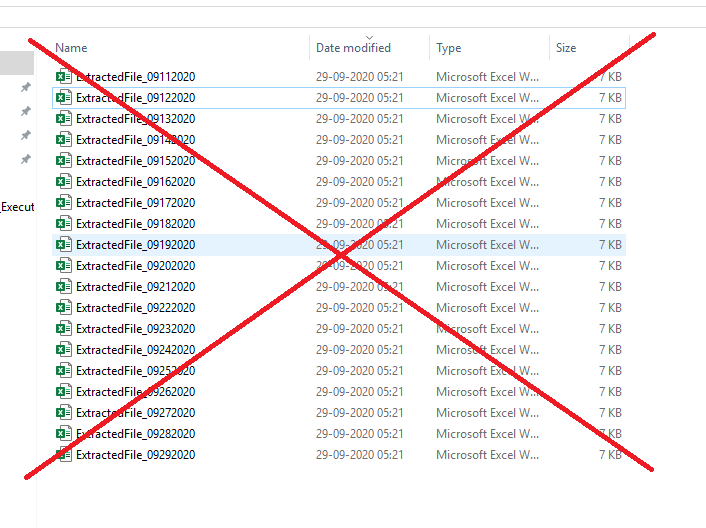

Scalability and Data Management:

- Monitait can handle vast volumes of data and complex relationships between records, crucial for tracking production in real time.

- Excel can become unwieldy with large datasets, potentially leading to data management challenges.

Automation and Workflows:

- Monitait allows for automated workflows, triggers, and alerts, streamlining manufacturing processes and improving productivity.

- Excel relies on manual inputs and lacks the automation capabilities needed for efficient production monitoring.

Real-time Collaboration:

- Monitait offers real-time collaboration, enabling multiple users to work simultaneously on the same data, fostering teamwork, and preventing version control issues.

- Excel often requires file sharing and manual updates, leading to collaboration challenges.

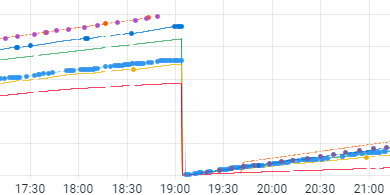

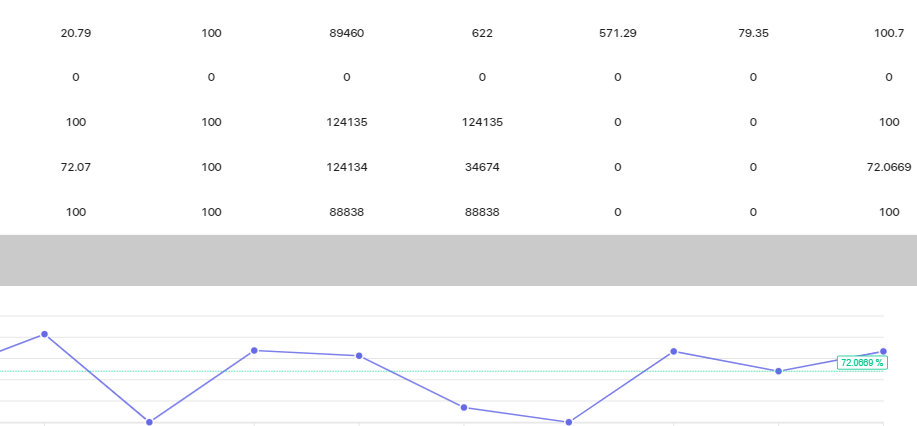

Robust Reporting and Analytics:

- Monitait provides tailored reporting and analytics tools, including customizable dashboards and charts, designed specifically for manufacturing needs.

- Excel can create reports but lacks the depth and specificity required for manufacturing analytics.

Integration and Unified Data:

- Monitait seamlessly integrates with various business systems, creating a unified view of manufacturing data.

- Excel may require manual data entry and lacks native integrations, leading to data silos.

Enhanced Security:

- Monitait prioritizes security with robust access controls, safeguarding sensitive manufacturing data.

- Excel files can be less secure, especially when shared or distributed.

Mobile Access for Operations:

- Monitait provides mobile apps for on-the-go access to manufacturing data, improving operational efficiency and connectivity.

- Excel lacks native mobile functionality, limiting accessibility for operations teams.

Ongoing Support and Updates:

- Monitait offers continuous support, updates, and new features as part of its subscription-based service.

- Excel typically relies on standalone software packages with periodic updates.

Overcoming Excel Limitations in Manufacturing:

- Shift Tracking: Monitait facilitates shift tracking seamlessly, ensuring accurate data recording.

- Daily Production Comparisons: Monitait simplifies daily production comparisons through automated calculations.

- Downtime Recording: Monitait enables real-time downtime recording, a critical aspect of efficient production monitoring.

- Product History and Linkage: Monitait makes it easy to find and understand product history and linkage, unlike cluttered Excel sheets.

- Applicability for Repetitive Tasks: Monitait is designed for repetitive manufacturing tasks, offering efficiency and accuracy over Excel.

While Excel has its merits as a general-purpose tool, Monitait's specialization in smart manufacturing, scalability, automation, and tailored features make it the superior choice for modern manufacturers. By choosing Monitait, manufacturers can elevate their production monitoring processes, increase efficiency, and maintain a competitive edge in the industry.