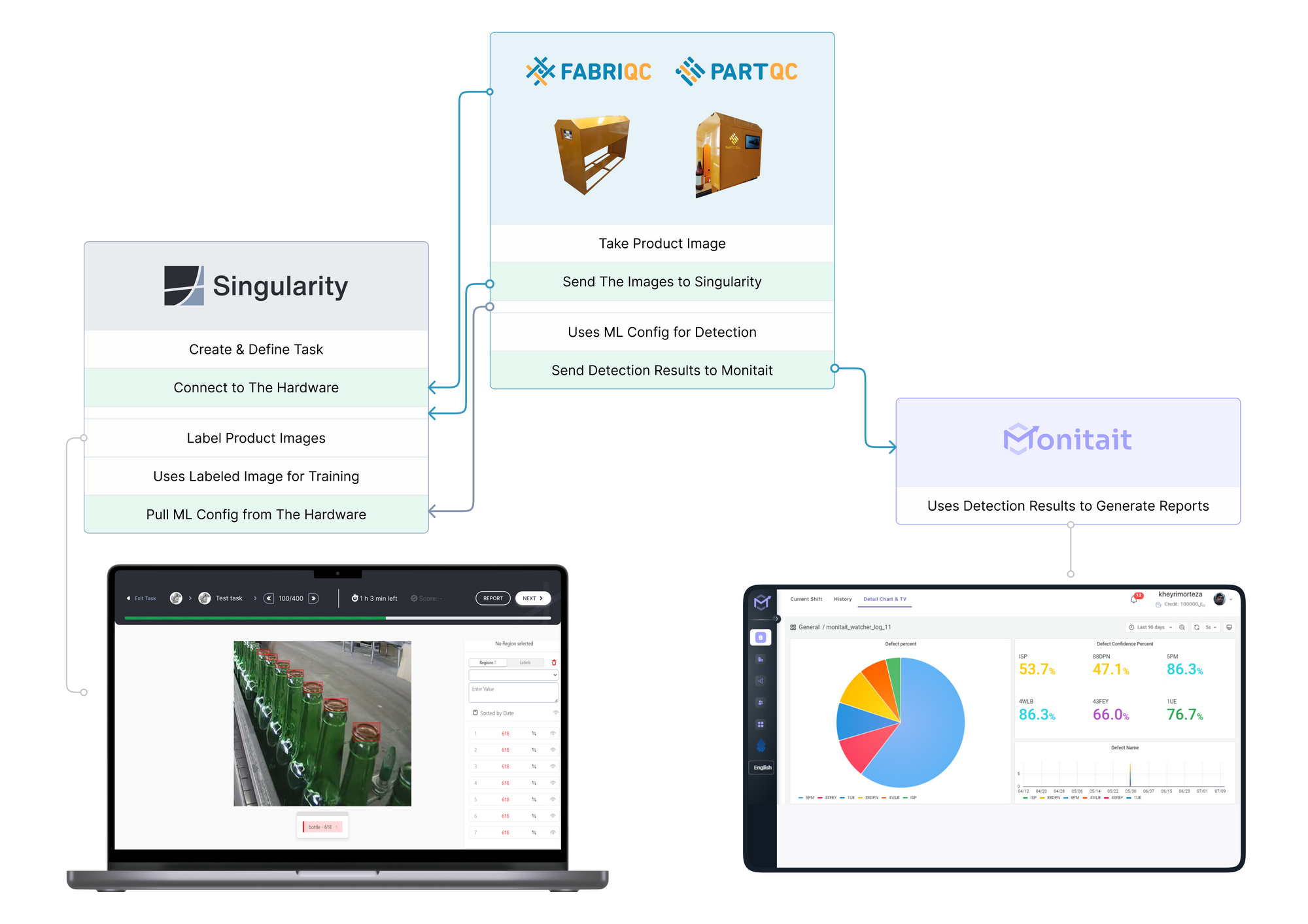

How does the Monitait NO-CODE ecosystem work

In today's dynamic manufacturing landscape, the pursuit of excellence calls for innovative solutions that deliver efficiency, precision, and real-time insights. Manufacturers worldwide are now discovering the transformative potential of cloud-based technologies to optimize Overall Equipment Effectiveness (OEE). Leading this charge are Monitait, FabriQC, and PartQC, each tailored to meet the unique demands of different manufacturing sectors.

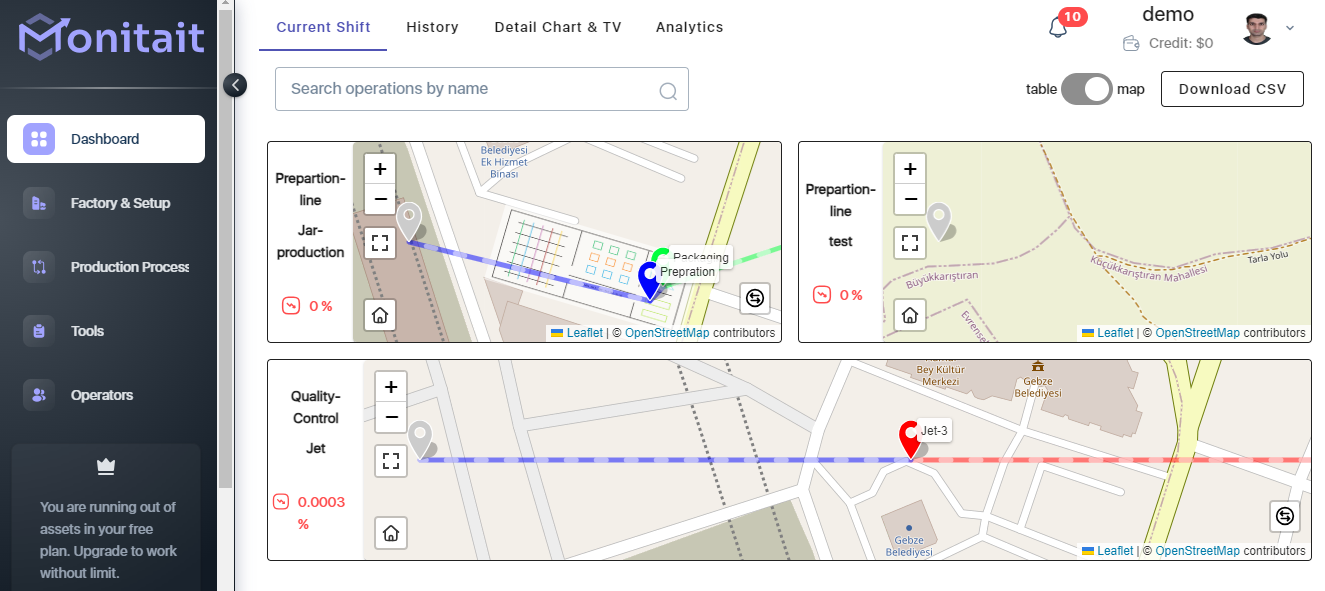

Monitait: The Unified Data Hub for OEE Insights

The cornerstone of manufacturing excellence lies in the ability to efficiently gather, process, and analyze data. Monitait stands at the center of this data-driven revolution, aggregating information from various sources including sensors, cameras, and user inputs. By creating a unified repository, Monitait equips manufacturers with a comprehensive view of their operations.

Crucially, Monitait operates within the cloud, securely housing data that is accessible from any location in real-time. This accessibility empowers manufacturers with the tools required for swift decision-making and streamlined operations management.

Singularity: A No-Code Revolution in Manufacturing

Singularity is a transformative no-code machine learning platform revolutionizing manufacturing. It empowers manufacturers to leverage the power of ML models without requiring extensive coding expertise. With its user-friendly interface, it simplifies the creation, training, and deployment of ML models, democratizing advanced technology for all. Swift training processes streamline complex algorithms and data preparation, while seamless hardware integration ensures that ML insights are immediately actionable. Singularity operates independently and integrates effortlessly with various hardware and software solutions, including Monitait. It offers real-time insights, redefines quality control with precise assessments, monitors efficiency, scales with evolving manufacturing needs, and delivers significant cost savings by reducing errors and optimizing production. Singularity is the game-changer manufacturing operators have been waiting for.

FabriQC and PartQC: Tailored Precision in Quality Control and Efficiency Monitoring

Quality control is an indispensable facet of manufacturing, and FabriQC and PartQC have emerged as industry trailblazers. These cloud-based hardware solutions employ the power of machine vision inspection, using cameras and machine learning to evaluate the quality of products on the production line.

FabriQC, meticulously designed for roll-based products like fabric, paper, and steel, capitalizes on machine vision technology. Images captured during the inspection process are sent to Singularity, an AI-driven platform. Singularity's machine learning algorithms analyze the images, generating machine learning configuration files. This closed-loop quality control system streamlines quality assessment, making it more precise and efficient, while reducing human error and ensuring unwavering high-quality standards.

PartQC, purpose-built for container-based products such as PET, glass, cans, and tires, redefines the landscape of efficiency monitoring. This cloud-based solution tracks the type of products on the production line and the desired quantity. This real-time data is indispensable for waste reduction, maintaining production speed, and maximizing efficiency.

Watchers utilize advanced technology, including cameras, to count the number of products at each station. The reliance on manual sampling is eliminated, human error is minimized, and manufacturers are armed with precise data for driving efficiency improvements.

Advantages of Cloud Manufacturing for OEE Optimization

The cloud-based approach presented by Monitait, FabriQC, and PartQC delivers a multitude of advantages:

- Real-Time Insights: Cloud technology provides instant access to data and insights from any location, facilitating prompt decision-making.

- Enhanced Quality Control: Automation and machine learning enhance quality control, reducing defects and maintaining superior product quality.

- Optimized Efficiency: Precise data and automation boost production efficiency, reduce waste, and enhance OEE.

- Cost Savings: Reduced errors and streamlined processes lead to significant cost savings.

- Scalability: Cloud-based solutions can easily adapt to accommodate evolving production needs.

A defining characteristic of Monitait, FabriQC, and PartQC is their user-friendly, no-code design, ensuring that manufacturing operators can harness the benefits of advanced technology without extensive coding or technical expertise.

In the era of cloud manufacturing, this collaboration between Monitait, FabriQC, and PartQC is a testament to the boundless potential for innovation, efficiency, and OEE optimization. By harnessing the power of the cloud, manufacturers can look forward to higher productivity, improved quality, and a competitive edge in an ever-evolving industry. The future of manufacturing is smart, cloud-connected, and teeming with possibilities, and these pioneering solutions are leading the way.