The Importance of Balancing a Production Line

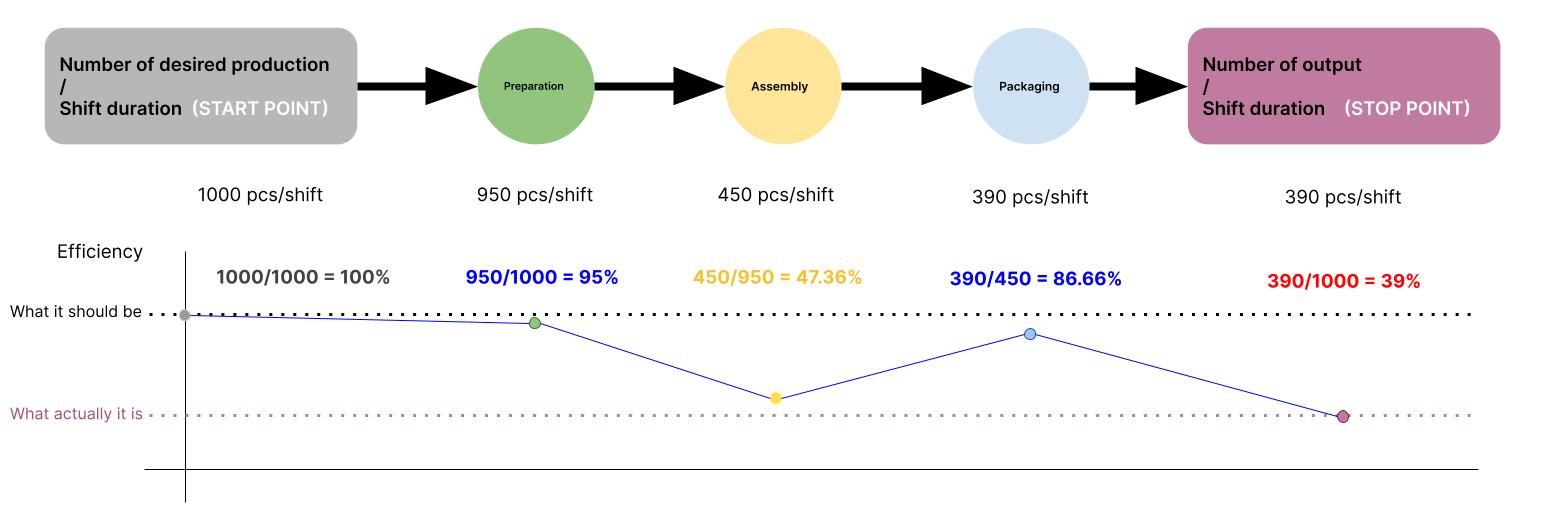

A well-balanced production line is essential for efficient manufacturing processes. When a production line is not balanced, it can lead to bottlenecks and hinder the development of products. considering the importance of a balanced production line, how to monitor and balance a production line?

A Simple Production Line and Identifying the Bottleneck:

To identify a bottleneck in your production line, you must analyze the data. Let's consider the following efficiency numbers for different stations from the above sample: [95, 47.36, 86.66]. In this case, it's evident that the assembly station is experiencing abnormal efficiency, indicating a bottleneck issue.

Resolving the Bottleneck:

The simplest and most effective solution to resolve a bottleneck is to double the capacity of the bottleneck station. In our example, doubling the number of assembly stations can significantly improve production efficiency.

keep it balanced by Monitoring:

Maintaining a balanced production line is an ongoing process. To achieve this, it's crucial to track the performance of every station daily and in real time. This proactive approach allows you to identify issues promptly and make necessary adjustments to keep your production line running smoothly. to achieve this real-time improvement you should leverage some people or apps like monitait.com to get these data and alarms continually.