Seriously, does OEE Production Monitoring System help my business?

Nowadays, factories are encountering lots of issues through their daily production; financial issues, lay off, outdated products, demand reluctance, lockdowns, and way more issues compared to a decade ago, IT helps factories work more efficiently by the power of their data, ERP, CRM, HRM, Inventory Management System and etc. are a sample of IT software to help businesses have a good plan through their production, through this IT eco-system of manufacturing, one part is just about to help a more transparent view of the factory by the digitalization of stations and bring Industry 4.0 and IIOT to the shop-floor of every manufacturing company, the Production Monitoring System is a system to fulfill this step

PMS at first glance seems easy to deploy, but most factories fail to fulfill it

So why production monitoring is very important?

first and foremost, how is possible to progress without knowing where we stand? the production monitoring is like the heart rate graph of our factory, it helps us identify what exactly our current status is and point out any arrhythmia, do we work well? should we change something? if yes, what?

secondly, in the current world, pricing and manufacturing are more about availability, efficiency, and quality rather than technology and uniqueness (just take a look at S&P500 top companies!), a production line with planned and smooth production, will be more robust to economic changes and the variation of demand, a factory with continuous and seamless production may sound more promising for clients, rather than an on and off production

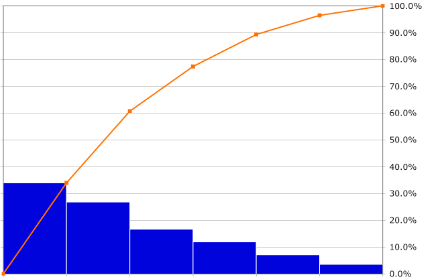

thirdly, monitoring helps us identify REALLY issues, as humans may affect by lots of circumstances and couldn't aggregate real issues in one mind, is it really the main issue made my factoriy down? better future production plans are feasible by a better comprehension of past valuable data

last but not least, real-time reporting the real-time issues is not possible until we can be aware of the factory shop floor at the moment

Wise manufacturer managers are more likely to follow trends, as it will let them be prepared for the future and its randomness, software can do best with the help of people who use it, which means the more your manufacturing staff work with it, the more it'll provide you the power of data!