How to analyze data from the shop floor and convert them to an insight?

Talking about the production line, there are some metrics that were discussed in OEE efficient manufacturing, what to monitor on the production line shop floor? post as a status quo of the production line scoring, what can give us more details of the shop floor

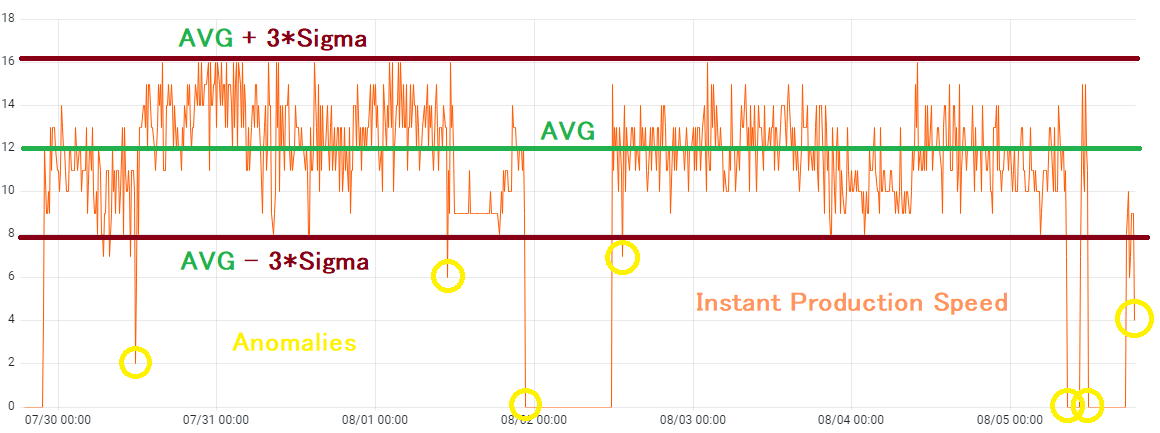

Speed Trends

the first way to optimize production line output is to find production line speed and try to keep the trend organized, normally the instant velocity of production in a short time should be constant with a normal variance, so the average production speed is the key to finding out what's going on at moment, have this chart as a sample to find anomalies you can use the old-school formula:

3*Sigma < | Speed(t) - Average(Speed) |

by finding anomalies you can alert anyone without any hesitation, those anomalies are the first sign of any trouble!

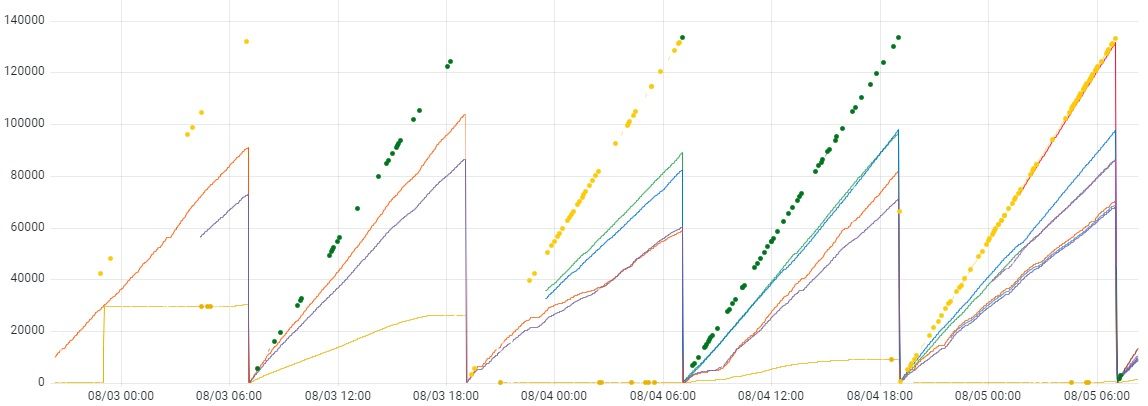

Desire vs Reality

Any factory machine is paid to work at its full potential, which means they were built for a nominal speed which guarantees its ROI (return on investment), so the managers should depict what's their real potential and what is their actual behavior, another simple formula will calculate the desirable production:

Productivity at moment=

( actual production * ( stop shift time - start shift time))/

( desirable production * ( moment time - start shift time ) )

This key metric will show do the factory work on its nominal heartbeat?

Bad Quality Reasons

in a competitive economy, any bad product leads to the loss of many current and future customers so Quality Control would be a big part of the production, but without nice logging data insight, there is no way to find the root causes and the problem will arise frequently, one of the most important parts of quality control is to report the details of production defective parts, through a normal human report or automatic Quality Control machines like FabriQC or PartQC, the final result would be something like a tag cloud which will show you where to put emphasize

Downtime reasons

any downtime means losing money, and there are typical reasons for downtime in any production line, from human reports to machine reports, understanding the histogram of downtime reasons

Special metrics for special industries

there are typical metrics for any sector of manufacturing, but any business need is unique, so the factory should define what are the key metrics for them and try to keep track of them